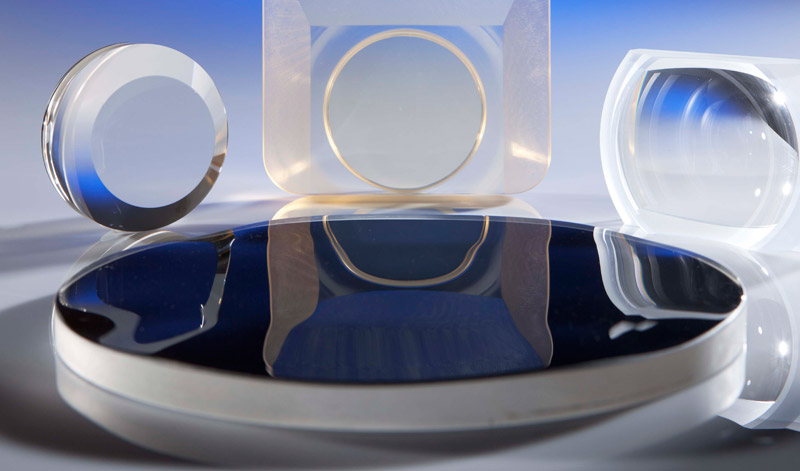

非球面和自由曲面

ZYGO 生产世界上最精确的非球面、球面和自由曲面光学元器件。这些产品的尺寸可以达到 600 mm,表面轮廓公差优于 100 皮米。为了说明这一点,想象一下,一个美国大小的光学元件,其表面精度却在一毫米以下!

-

更多信息

-

宣传册

-

技术论文

-

视频

超精密表面:

- 许多几何形状,尺寸高达 600mm:

- 轴上和离轴非球面。

- 自由曲面(非旋转对称)

- 球面

- 轴棱锥

- 相息图和其他衍射表面

- 我们还可提供轻量级和复杂的机械几何形貌

- 在材料方面几乎不受限制。我们的材料范围很广,包括:

- 低膨胀陶瓷:Zerodur、Clearceram、ULE 等

- 硬质材料:碳化硅(SiC)、氮氧化铝、尖晶石

- 软性材料:氟化钙(CaF2)、氟化镁(MgF2)

- 标准玻璃:BK7、SF-11

- 其他晶体材料:锗(Ge)、硅(Si)

- 金属:铝(Al)、镍(Ni)

- 极高的表面亚埃轮廓精度。整体表面面形误差几十皮米是可能的!

- 可控的中频面形误差。

- 极低的粗糙度,保证在空间周期内低至 10 微米。

- 一系列完整的制造技术:

- 计算机控制光学表面处理(CCOS)

- 离子束加工(IBF)

- 磁流变精加工(MRF)

- 精密光学和 CMM 计量

- 物理零透镜或计算机生成全息图(CGH)

The Way Ahead When Commercializing Space Optics

The Way Ahead When Commercializing Space Optics

The Way Ahead When Commercializing Space Optics

4 Big Mistakes in Developing Photonics-Enabled Medical Devices

A Technique to Control Global Figure Using Acid Immersion and Zernike Decomposition

Application of precision diamond machining to the manufacture of microphotonics components

Bound-abrasive polishers for optical glass

Coating High Quality Custom Optics: Risk Reduction Through Supplier Evaluation

标题

文件

下载链接

A Technique to Control Global Figure Using Acid Immersion and Zernike Decomposition

Document技术论文

下载链接 下载

Application of precision diamond machining to the manufacture of microphotonics components

Document技术论文

下载链接 下载

Combined advanced finishing and UV-laser conditioning for producing UV-damage-resistant fused-silica optics

Document技术论文

下载链接 下载

Computer control and process monitoring of electrolytic in-process dressing of metal bond fine diamond wheels for NIF optics

Document技术论文

下载链接 下载